Remote Monitoring Saves Hotel Thousands in Chemical and Water Costs

Objective/Challenge/Issue/Problem: Cooling towers for this hotel are located on the roof of an adjacent building and are not readily accessible. Therefore, it is difficult to know if the towers are functioning properly on a daily basis.

Proposed Solution: KBG Technologies’ IntelliSense™ provided remote monitoring and control for the facility’s cooling towers. This digital technology provides real-time information for the water system associated with the cooling towers. This information is monitored 24/7 and sensor alarms are programmed to notify the KBG team. The KBG team investigates the alarm data to determine possible cause and offer the facility the best possible advice.

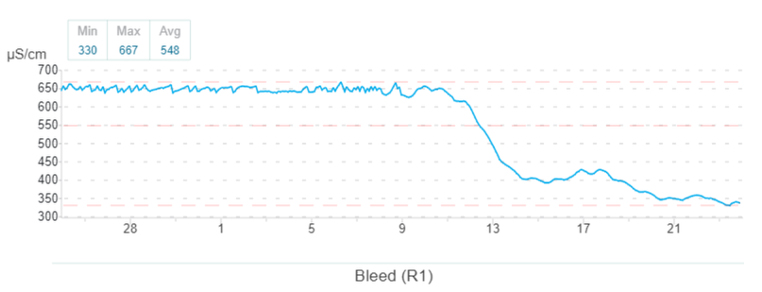

Benefit/ROI: The IntelliSense system identified a significant drop in conductivity in the system and increase in the usage of chemistry to treat the water. The KBG team contacted hotel management to make them aware of the situation and aided in troubleshooting probable causes. After eliminating potential issues in the mechanical room, the customer was asked to visually inspect the cooling towers. Upon inspection, staff determined that the tower float valve was broken, and the tower was overflowing.

Although the problem was identified the same day, it took a week to fix the float valve. During that week, the tower consumed the equivalent of two months of chemistry operating under normal conditions and used significant amounts of water. Without IntelliSense, the hotel might not have detected the broken tower float valve until KBG’s next monthly visit to the facility. The cost of chemistry and water avoided with early detection more than paid for the annual cost of IntelliSense!

Conclusion: IntelliSense assisted KBG and its client in identifying an unpredictable situation immediately. The client was able to begin the repair process and minimize the amount of chemical and water usage.

June 19, 2025

June 19, 2025