The Benefits of Molded Pulp

Make the Switch from Foam or Plastic

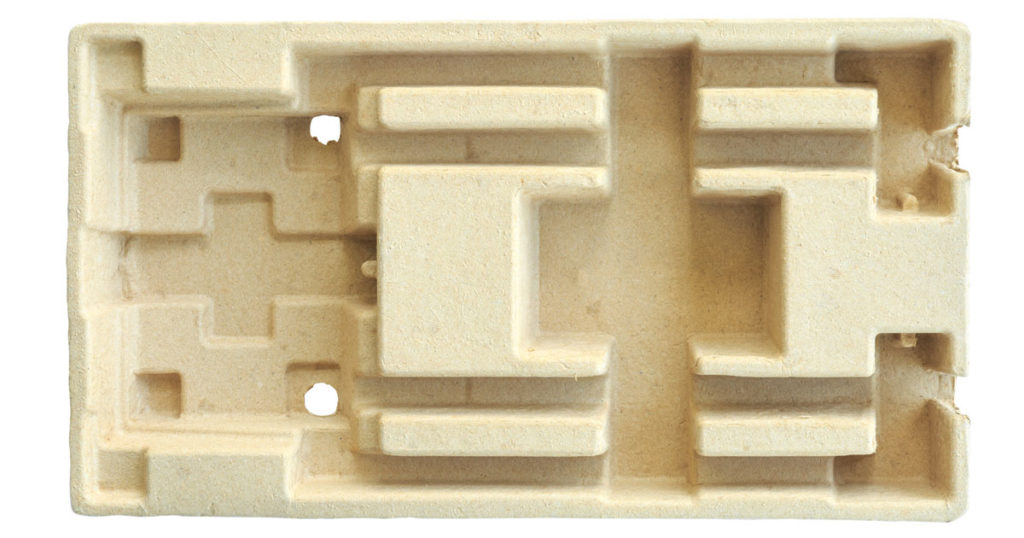

You may recognize molded pulp as the packaging material for egg cartons or drink trays. But over the past few years, it’s become an increasingly popular choice for both manufacturers and consumers. If you’re thinking about making the switch from foam or plastic, then molded pulp can offer countless benefits in production and performance.

Profitability

Simply put, molded pulp saves space, time and money. Its nestable, stackable design can cut shipping volume by as much as 50 percent, allowing you to move more units per truckload. With less frequent shipments, you can save on labor. And during transit, molded pulp passes the drop test and the shock test — with superior resistance to vibration, water and weather.

Recyclability

With only 14 percent of plastic packaging being recycled and over 40 percent winding up in landfills, the packaging industry must take steps now to stop plastic pollution. Molded pulp is already made with postconsumer paper, offering manufacturers a more recyclable and responsible solution than plastic. And after use, molded pulp can be recycled again. In fact, two-thirds of packaging material recovered for recycling is paper — more than the total of glass, metal, and plastic combined.

Sustainability

But sustainable consumption and production requires more than recycling. And in order to truly transform our “take, make and waste” economy, we must transition from a linear to a circular supply chain that reduces waste and reuses resources. For centuries, pulp and paper mills have succeeded with circular supply chains that recycle products and repurpose byproducts. Molded pulp manufacturing makes new use of side streams — such as sludge, ash, lignin and wastewater.

With all the above benefits and more, molded pulp offers cleaner, greener packaging that can have a big impact on your bottom line. KBG’s chemistries and technologies for recycled packaging mills provide innovative solutions for your competitive edge. From machine speed to plybond strength, we can help customers deliver quality, save energy and reduce costs. Contact us today to start a conversation.

November 25, 2019

November 25, 2019